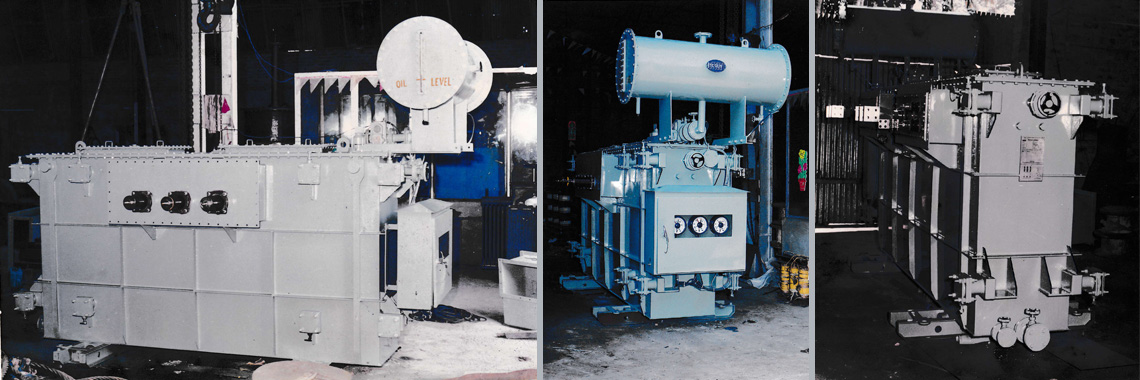

Induction Furnace Transformers

- Home /

- Induction Furnace Transformers

Induction Furnace Transformers

Designing

The greatest aspect of a furnace transformer is its Electrical Designs. Which need selection of proper conductor size, type of coils used and selection of current density of copper conductor and flux density of CRGO core. For OFWF transformers, special care is taken for its better cooling under forced water system.

Coil Construction

Coil design and quality are key to transformer efficiency and longevity. Tesla designs coils specifically for each application. We use thermally upgraded paper for longest insulation life.

Core Construction

Design:

The core is designed with optimum flux density to minimize core loss and cost.

Materials:

AISI-grade - H0, M3, M4 or other - high - permeability CRGO steel Laminations is used.

Construction:

The laminations are handled with minimum bending to preserve the low loss properties. The core is clamped in a rigid frame with uniform pressure to reduce mechanical effect on performance.

Core & coil Assembly

The core-and-coil assembly and all current - carrying parts - are immersed under oil in a controlled environment preventing contamination by ambient outdoor air, industrial environments, salt spray and other.

Tank and Radiators

The tank is fabricated of high-quality, heavy-gauge steel plate. It is designed to withstand operating pressure and vacuum as well as the stress of shipping, rolling and jacking.

Final Assembly

Fittings, gauges and controls are assembled on the tank. Control wiring is completed and tested and the core-and-coil assembly is placed in the tank after necessary treatment to improve IR value.

Bushing and other equipment are installed and wired after the coils are covered with oil in a controlled environment.

The tank surface is cleaned to prepare for protective coating for the industrial environment. After a though leak check the tank is covered with a rust-inhibiting primer. After drying, two coats of gray enamel paint are applied for a durable and attractive finish.

Testing

The company has the facility to conduct all standard routine test as per IS 2026 and conducts the entire test before dispatch to ensure the materials has trouble free at the customer premises.