Dry type Transformers

- Home /

- Dry type Transformers

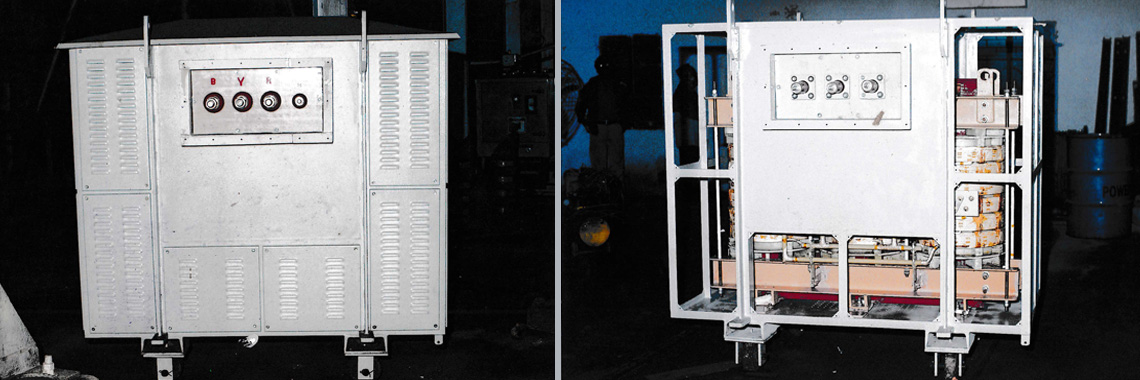

Dry type Transformers

Dry type transformers are class 'H' type insulated. The insulating materials used for these type of Transformers, having high dielectric strength and are capable to withstand high temperature. The temperature withstanding capacity is generally made to comply with IEC 76/IS 2026/IS 11171.

Availability:

- Open execution type for installation in an existing panel or enclosure.

- Well-Ventilated enclosure with lip cut louvers and baffles for indoor installation.

- Non Ventilated enclosure for outdoor installation.

Advantages:

- Use of non-biodegradable materials makes these suitable for strict environmental conditions.

- No fire or explosion hazards because of use of non-flammable materials and absence of any liquid insulation.

- Non-requirement of oil sump makes these ideally suitable for installation near load centers thus reducing cabling costs and improving voltage regulation.

Zero Maintenance:

- Drastically reduced maintenance and clear looks due to the absence of any insulating liquid.

- A life cycle analysis would revel the cost – effectiveness of Dry Type Transformers in long run through it requires a higher initial cost.

- Easy handling and access to active parts for inspection.

Dry type Transformers are ideally suitable for installations in

- Underground gassy mines.

- Petrochemical refineries.

- Multistoried buildings.

- Business Blocks & Supermarkets.

- Congested Metropolitan urban areas.

- Underground Railways.

- Airports.

Ranges:

Present product range includes transformers up to 3000 KVA, 11 KV class and Motor stating auto-transformers for motor up to 1500 KW, 6.6 KV class.

Electrical Components: the coils and all current- carrying parts – are vacuum impregnated with silica-varnish or ragin casted under vacuum in a controlled environment preventing contamination by ambient outdoor air, industrial environments, salt spray and other.

Coil Construction:

Coil design and quality are key to transformer efficiency and longevity. TTE designs coils specifically for each application. We use thermally upgraded insulation(nomex) for longest insulation life.

Tubular cooling ducts formed with rigid, high–density spacers facilitate free air circulation. The coils are vacuum impregnated with very high quality varnish. Very high insulation value and moisture Quality – Upon completion each coil is evaluated and tested.

Built-lap, miter or step-lap-miter(above) construction is chosen based on the application and core loss requirements.

Core Construction:

Design:

The core is designed with optimum flux density to minimize core loss and cost. Built-lap, miter or step-lap-miter construction is chosen based on the application and core loss requirements.

Materials:

AISI-grade –H0, M3, M4 or other – high – permeability steel is used. Laminations are burr free and very thin – between 0.007 and 0.013 inch, varying no more than +-0.002 inch in length for the lowest sound level and excitation currents. Each lamination is covered with a high- resistance, inorganic coating to reduce eddy currents.

Construction:

The laminations are handled with minimum bending to preserve the low loss properties. The core is clamped in a rigid frame with uniform pressure to reduce mechanical effect on performance.

Cabinets

The cabinet is fabricated of high-quality, heavy-gauge steel plate. It is designed to withstand the stress of shipping., rolling and jacking.

Final Assembly

Fittings, gauges and controls are assembled on the cabinet. Control wiring is completed and tested and the core-and-coil assembly is placed in the cabinet after necessary treatment to improve IR value.

Bushings and other equipment are installed and wired after the coils are covered with oil in a controlled environment.

The Cabinet surface is cleaned to prepare for protective coating for the industrial environment. After a though leak check the tank is covered with a rust-inhibiting primer. After drying, two coats of gray enamel paint are applied for a durable and attractive finish.

Testing

The company has the facility to conduct all standard routine test as per IS 2026 and conducts the entire test before dispatch to ensure the materials has trouble free at the customer premises.